Gen 49D is an alcohol free lubricant formulated to separate water and provide diesel fuel system performance improvements. Gen 49D is specifically formulated to separate water and provide complete diesel fuel system performance improvements. Gen 49D is specifically formulated to meet all manufacturers requirements including GM, Caterpillar, Cummins and Detroit Diesel.

Gen 49D fights water and gelling the leading problem with winter fuel. Cold flow is improved up to 27oF (15oC). This gives your fuel the very best chance of flowing in extreme cold conditions. Gen 49D contains a powerful deicer that lowers the freeze point of water and prevents ice crystals from forming that may plug filters and cause misfiring. Additionally the antigel characteristic keeps crystal molecules from collecting or clumping to ensure problem free winter operation.

Gen 49D adds an excellent stabilizing package to your diesel fuel. High temperature stress on fuels results in degradation products such as particulate solids which may lead to injector damage and filter plugging. Gen 49D also fights the effects of oxygen and water in stored fuel, neutralizing the effect of water.

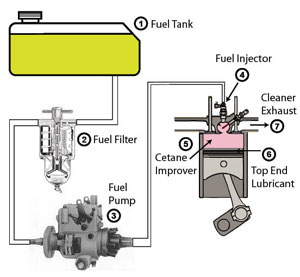

Diesel fuel is corrosive by nature and corrosion products such as iron oxide cause filter plugging and injector damage. Gen 49D fights corrosion and rust in the fuel tank and through the entire fuel system.

Poor injector spray patterns result in poor combustion and fuel economy while injectors treated with Gen 49D remain clean with a good spray pattern insuring optimal performance.

|

|

|

Starting your equipment each day can seem to be the easiest of all tasks....that is until it won’t start. All the proprietary components of Gen 49D working together ensure exceptional starting efficiency especially in cold conditions. Gen 49D will save unnecessary strain on starters and high stress on batteries. One of the first benefits our customers report is how much easier their equipment fires after applying Power Up Gen 49D for the first time.

Gen 49D contains a powerful synthetic lubricant package which reduces friction and wear in the top end of the cylinder, injectors and fuel pump. Poor fuel lubricity is commonly seen in new low sulphur fuels. Gen 49D is approved for and surpasses the new standards for diesel fuel and exhibits wear and friction reduction significantly below typical levels. Poor fuel lubricity results increased maintenance costs, downtime and poor fuel economy. In the HFRR test, we see typical fuel measure in excess of 500 microns of wear, the 2005 standard will be 460 micron of wear.

Gen 49D protects your fuel pump, the injectors and top end of the engine from premature wear and failure, reducing costs and increases life over straight diesel fuel.

The preflame region before fuel enters the combustion chamber is only a small part of the complete lubrication protection offered by Gen 49D. Gen 49D is designed and formulated to lubricate the top end of the combustion chamber where the severe stresses of burning new, dry low sulphur fuels are causing premature wear and poor performance. Fuel injectors, intake and exhaust valves and piston rings are being subjected to more extreme conditions than ever before.

| Typical Properties | ||

| Property | Method | Result |

| Appearance | Clear, Light Amber Liquid |

|

| Color | ASTM D1500 | 3.5 |

| Viscosity @40°C (104°F) | ASTM D445 | 5.8 cSt |

| Density @20oC (68oF) | ASTM D941 | 0.925 g/mL |

| Pour Point | ASTM D97 | -40oF (-40oC) |

| Flash Point (COC) | ASTM D92 | 169oF (76oC) |

| Fire Point (COC) | ASTM D92 | 172oF (78oC) |

| BOCLE Fuel Lubricity - Neat #2 Diesel - Diesel & 800 ppm Gen 49D |

ASTM D5001 | 0.615mm 0.510mm |

| HFRR Fuel Lubricity - Neat #2 Diesel - Diesel & 800 ppm Gen 49D |

0.556mm 0.353mm |

|

| Rust Prevention - Neat #2 Diesel - Diesel & 800 ppm Gen 49D |

ASTM D665 | 27% Surface Rust 0% Surface Rust |

| Pour Point - Neat #2 Diesel - Diesel & 800 ppm Gen 49D |

ASTM D97 | -2oF (-19oC) -24oF (-31oC) |